Filter your solution

To help find your product of interest we have developed this product finder. The product finder provides the possibility to filter on product group, specific product types, application and brand. The filters can be used separate and in combination.

Showing all 61 results

-

-

-

-

-

-

-

-

-

-

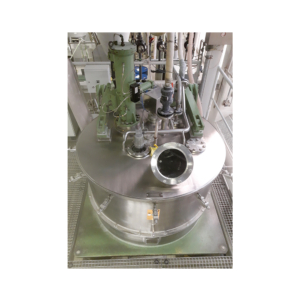

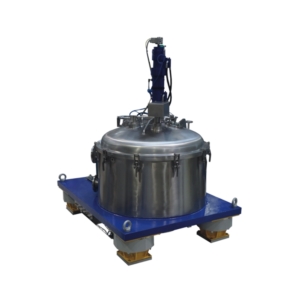

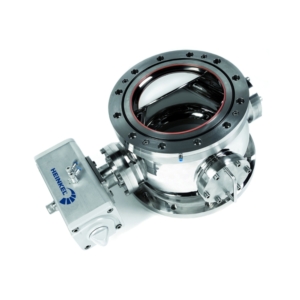

Pilot Plant Filter Dryer & Vacuum Dryer

Filters & Filter DryersPressofiltro® / Turbodry® Series PF/TD 5 - PF/TD 100

-

-

-

-

-

-

Pilot Plant BS-pilotDRYⓇ

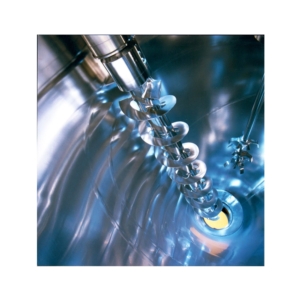

Conical Screw Vacuum Dryers, Conical Screw Mixers & CookersSeries ML001 - ML010

-

Laboratory System BS-miniDRYⓇ

Conical Screw Vacuum Dryers, Conical Screw Mixers & CookersSeries ML015-ML005

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

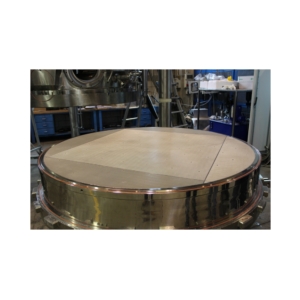

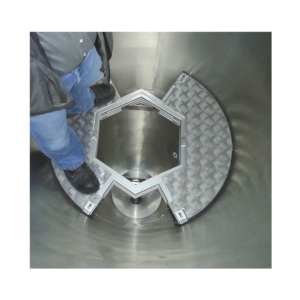

Working Platforms for Conical Dryers

Conical Screw Vacuum Dryers, Conical Screw Mixers & Cookers

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-